Driving Directions | Toll-Free: 1-800-331-1801 | Phone: 419-739-4900 | Fax: 419-738-9058 | info@gawintzer.com

HISTORY

ABOUT OUR HISTORY

G.A. Wintzer & Son Co.

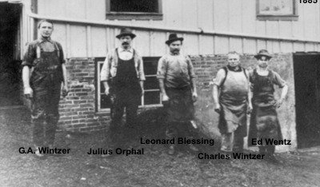

The beginnings of G.A. Wintzer & Son Co. can be traced back to the 1840s when an early pioneer in the Wapakoneta area, Gotlieb Machetanz was purchasing hides and skins with the Shawnee Indians along the Auglaize River. In 1848 Gotlieb’s nephew, Charles Wintzer, moved to Wapakoneta to join his uncle in the family business.

In 1857, before Abraham Lincoln was even president, Charles took over the business and changed the name to the Charles Wintzer Tanning Company. Charles continued to purchase and tan hides and skins for sale as strap and harness leather goods. At the turn of the century the decision was made to discontinue tanning operations although, they continued to buy hides and skins; curing them with salt to sell to other tanneries.

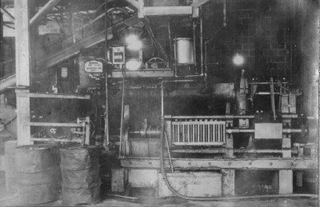

In the early 1920’s the G.A. Wintzer & Son Co. was formed to replace the Charles Wintzer Tanning Company by Charles’ son G.A. and his grandson Carl. Rendering operations then began to compliment the hide and skin business. Initially, open kettles were used in a lean-to shack attached to a slaughter house north of town where later, their original plant was built.

In 1943 Carl’s son Frederick took over the family business after Carl’s passing. A few short years later, the Wintzer plant caught fire and was burnt to the ground. A new plant was built 2 miles South of Wapakoneta at its current location where they would continue to manufacture high quality protein meals to be used as an ingredient in livestock feed and pet food. Fred later purchased and installed one of the first Dupps continuous rendering cookers in the industry and he also, developed and patented a few tools and technologies that are still used in the industry today.

In 1989 Fred’s eldest son Gus and third son Carl assumed President and Vice President positions at the company. In 1988 Wintzer began servicing the inedible material for Cooper Farms new Turkey plant in St. Henry, OH. Shortly after this, the Coopers invited Wintzer to their first Ohio Poultry Association event and they quickly realized they were surrounded by a growing Poultry Industry. After several upgrades to various equipment and procedures, Kirk Azbell was tasked with marketing and securing the business of other laying companies throughout the states of Ohio and Indiana.

The mid 90’s brought with it two large chicken processors from Indiana - a broiler operation and a spent hen operation. In addition to this period of time, a major expansion was occurring in the restaurant industry. Besides manufacturing quality protein meals; Wintzer also, collects used cooking oil which is then refined and repurposed into a calorie source for animal feed.

Today G.A. Wintzer & Son Co. services a large amount of laying companies and feed mills throughout all of Ohio and much of Indiana. The company picks up thousands of restaurants and a variety of grocery stores, food processors, butcher shops and small mom and pop food operations throughout a 5 state region. They collect millions of pounds of raw material per week and recycle that material back into usable products. The rendering process provides an essential link in the human food chain and is essential to the recycling industry as a whole.

Any information collected will be used solely by G.A. Wintzer & Son Co. to follow through on your request for additional information. G.A. Wintzer & Son Co. will maintain such information in confidence and does not sell contact information to third parties.